Sustainable and Eco-Friendly Dyeing Units in Tirupur Region: Green Manufacturing Guide

Sustainable eco-friendly dyeing units Tirupur represent a growing trend in the textile industry’s transformation towards environmental responsibility. Tirupur’s dyeing industry is increasingly adopting sustainable and eco-friendly practices to meet international standards and consumer demands. This comprehensive guide highlights green dyeing units and sustainable manufacturing methods in the region, providing insights into how sustainable eco-friendly dyeing units Tirupur are revolutionizing the industry.

Table of Contents

Eco-Friendly Dyeing Practices

Low-Temperature Dyeing: Reduces energy consumption 30-40%. Uses improved dyeing techniques. Lowers chemical usage significantly. Reduces water waste. Cost-effective long-term.

Organic Dyes: Plant-based and natural dyes. Biodegradable and non-toxic. Meet international standards. Higher cost initially. Growing market demand.

Water Recycling Systems: Advanced wastewater treatment plants. Recycle 70-80% of water used. Reduce fresh water intake. Save costs through reuse. Meet environmental regulations.

Chemical Management

Reduced Chemical Usage: Minimize hazardous chemicals. Use GOTS-approved dyes only. Proper chemical storage and disposal. Regular monitoring and audits. Certification programs.

Zero Liquid Discharge: Treatment systems eliminate liquid waste. Convert waste to useful byproducts. Meet government requirements. Premium pricing possible. Certifications available.

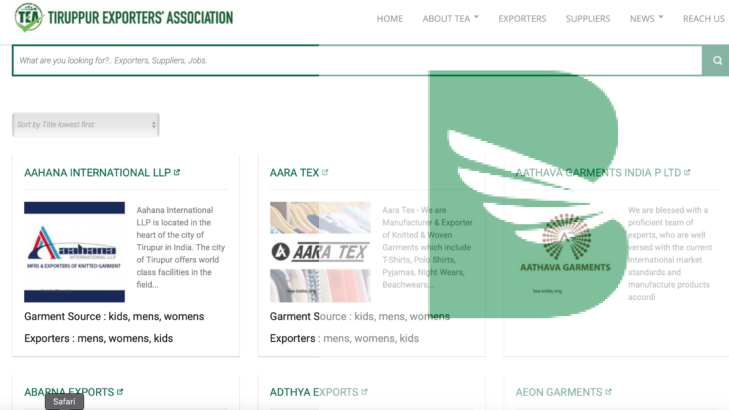

Tirupur Eco-Friendly Dyeing Units

Many units in Tirupur have adopted sustainable practices. Look for certifications like GOTS, OEKO-TEX. Check for ISO 14001 environmental certification. Verify water treatment facilities. Request audit reports.

Benefits of Eco-Friendly Dyeing

Environmental Protection: Reduce water pollution. Minimize chemical discharge. Lower carbon footprint. Preserve natural resources.

Business Advantages: Meet international buyer requirements. Premium pricing for eco-friendly products. Improved brand reputation. Long-term sustainability.

Compliance: Meet Indian environmental regulations. Satisfy international standards. Avoid penalties and shutdowns. Future-proof operations.

Cost Considerations

Initial Investment: Equipment upgrades expensive. Implementation costs high. Training required. Timeline for payback 3-5 years. Long-term savings justify investment.

Operational Costs: May slightly increase initially. Energy savings offset expenses. Water reuse reduces costs. Chemical reduction lowers expenses.

FAQ

Which certifications matter most?

GOTS for organic. OEKO-TEX for chemical safety. ISO 14001 for environmental management. Sedex for social compliance.

How to identify eco-friendly units?

Check certifications and documents. Request facility tours. Ask for sustainability reports. Verify third-party audits.

What is zero liquid discharge?

Treatment systems that eliminate all liquid waste. Convert to usable byproducts. Highest environmental standard.

Costs vs benefits analysis?

Initial high costs. 3-5 year ROI. Long-term savings significant. Premium market access. Risk mitigation value.

Pros and Cons

Pros:

Environmental responsibility

Higher market value

International compliance

Long-term cost savings

Brand reputation

Cons:

High initial investment

Complex technology

Requires skilled workforce

Higher operational costs initially

Limited supplier options

Conclusion

Sustainable dyeing practices are essential for Tirupur’s future. Eco-friendly units offer environmental and business benefits. Look for certified suppliers with proper infrastructure. Green dyeing is becoming industry standard. Choose sustainable partners for responsible sourcing.

Implementation Guide for Sustainable Eco-Friendly Dyeing Units Tirupur

Implementing sustainable eco-friendly dyeing units Tirupur requires careful planning and strategic investment. Organizations must assess their current dyeing processes, identify inefficiencies, and develop a comprehensive sustainability roadmap. The transition to sustainable eco-friendly dyeing units Tirupur begins with a thorough environmental audit of existing facilities. This audit helps identify areas where sustainable eco-friendly dyeing units Tirupur can significantly reduce environmental impact and operational costs.

Future Outlook for Sustainable Eco-Friendly Dyeing Units Tirupur

The future of sustainable eco-friendly dyeing units Tirupur looks promising as global textile brands increasingly demand environmentally responsible manufacturing partners. Investment in sustainable eco-friendly dyeing units Tirupur represents not just environmental stewardship but also smart business strategy. As regulatory pressures mount and consumer preferences shift towards eco-conscious products, sustainable eco-friendly dyeing units Tirupur will become the industry norm rather than an exception. This transformation positions Tirupur as a leader in sustainable textile manufacturing globally.

For businesses considering sustainable eco-friendly dyeing units Tirupur, the time to transition is now. Contact certified suppliers and begin your sustainability journey today.

Leave your comment